Product quality is always what our customers and ourselves concern most. We work hard to achieve maximum customer satisfaction by providing our customers with superb expanded metal products. We have established a complete set of quality control system and passed ISO 9001 and SGS certification. Our dedicated quality analyzer team implement strict quality control in every phase of production from raw material purchasing, during the production, finished product packaging and final perfect delivery.

Our raw material steel plates come from Baosteel, Shougang Group and other well-known suppliers. Besides, out quality inspector will test chemical composite, sizes and other relevant items when receiving the raw materials to ensure the raw materials received meet or even exceed corresponding quality standards and requirements.

New punching mould

Flatness testing

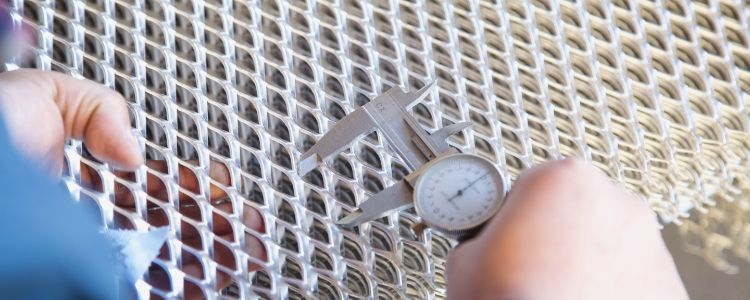

Mesh opening testing

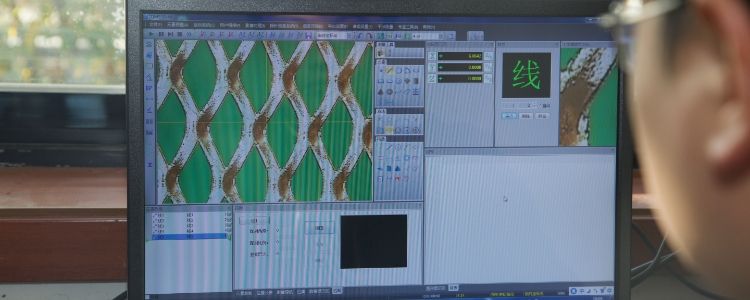

During the production process, our technicians carry out real-time monitoring on punching, flattening, shearing and leveling links. On the one hand, we can test product quality at any time; on the other hand, we can find the the deficiencies in the production process and constantly improve our production line and product quality.

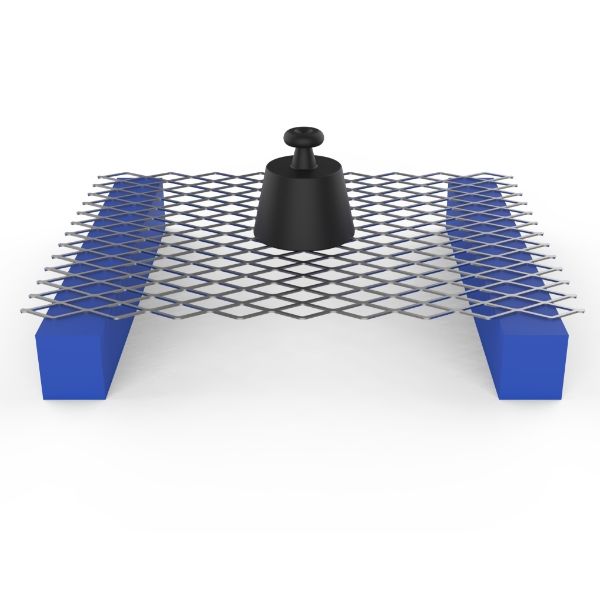

Load bearing capacity test

Galvanized coating test

Small hole expanded metal testing

We have independent laboratory to perform raw material chemical composite analyze, mesh opening testing and product performance testing to ensure our products comply with manufacturing tolerances and have best load bearing capacity and corrosion resistance. Besides, we can supply corresponding test reports to make you have confident in using our products in your specific applications.

According to the chemical and physical properties of the products, we use waterproof, moisture-proof and breakage-proof materials for packaging to avoid product damage during transportation. In addition, we can also provide customized packaging according to customer's specific requirements to meet the special needs of different customers.

We record the test results of every link of expanded metal production process for reference to help us find out the root cause quickly when quality problems are tested and solve these problems accurately.